Patch Cord

Patch cords are cables with connectors on both ends that connect devices to power sources. Cables connect electronic devices. The ropes are colored and range in length from 3 inches to 20 feet. Ethernet patch cords are used to construct home computer networks. These sturdy and flexible cables use standard wrapping. Crossover cables connect two computers directly.

How to Choose Fiber Patch Cords

Various types of fiber optic patch cords are available. This description divides patch cords into ordinary and unique varieties. Fiber patch cords can be categorized by cable mode, transmission mode, jacket type, connector type, and polishing type.

Single-Mode Fiber Patch

Single or multimode indicates how light travels in fiber patch cables. Single-mode and multimode fiber cables exist. Single mode fiber patch lead permits only one mode of light to flow throughout its length, therefore it can transmit signals at higher speeds with lesser attenuation. OS1 and OS2 are different in architecture and application. OS1 and OS2 SMF Cables compares them. OS1 and OS2 both support long-haul transmission, however OS2 offers superior performance with less losses.

Multimode Fiber Patch Cord

The multimode fiber patch cord’s larger core, 50 or 62.5 microns, transmits numerous light modes. It comes in five varieties with differing transmission rates or distances: 62.5-micron OM1, 50-micron OM2, 50-micron OM3, 50-micron OM4, and 50-micron OM5. Multimode fiber jumpers can cover a small distance due to the cable’s numerous light streams. Multimode patch cords are suitable for short-distance transmission within a building or campus.

Simplex VS duplex

There are simplex and duplex fiber patch cords. It can be coupled to one-port BiDi transceiver modules. Duplex patch cord has two glass or plastic strands and one duplex connector (or considered as two simplex connectors). It’s typically used with common or BiDi transceivers.

Same-connector type and hybrid fiber patch cord

Same-connector type fiber patch cord and hybrid fiber patch cord are separated by whether each end has the same connector. Same-connector fiber patch cords include LC to LC, SC to SC, etc. The ends of hybrid fiber patch cords, such LC to SC, have distinct connections. If both devices have the same port type, consider a fiber patch cord with the same connector or a hybrid.

Unique Types Of Patch Cords

- Patch Cord Armor

Armored fiber patch cord preserves all typical features. Their design makes armored fiber patch cords anti-rodent and adult-step-resistant. Armored fiber patch cord is as flexible as conventional fiber optic patch cord and may be randomly bent. Innovative core design and low macro-bending sensitivity reduce further cable bend losses.

- Bend-insensitive fiber patch cord

Bend-insensitive fiber patch cord supports data center, FTTH, and high-density cabling with tight corners. Bend-resistant fiber patch cables are explained. This duplex multimode patch connection begins with a short length of single mode fiber. It solves the problem of utilizing single-mode equipment on multimode cable.

- Mode conditioning fiber patch cord

Mode conditioning fiber patch cable extends the reach of installed fiber plant and improves data signal quality. Mode Conditioning Patch Cord Used in 1/10 Gigabit Ethernet Applications has more information on typical uses. Mode-conditioned fiber patch cable Low-loss fiber patch cord LL

- Low Insertion Loss Fiber Patch Cords

low insertion loss fiber patch cords have lower connector insertion loss than conventional fiber patch cords, yet they look comparable. Common fiber connectors have 0.75dB insertion loss, while low loss fiber patch cords can be 0.2dB or below. This type of fiber patch wire is utilized when attenuation loss is important. Reduced attenuation expands the network’s long-haul reach.

- Fiber Patch Uniboot

Uniboot fiber patch cable unites two fibers in a single cable and is ideal for high-density cabling settings. It reduces cable count by 50% compared to regular LC cables and is suitable for tight spaces.

What exactly is a Pig Tail Fiber Optic?

A fiber pigtail is a specialized type of hardware connection that is utilized in the process of cable termination. One end of the cable on a fiber pigtail consists of bare exposed fiber, while the other end of the wire features a connector that has already been attached. Pigtails made of fiber are typically crimped onto individual strands of a multi-fiber trunk cable during the splicing process.

The Explanation of the Pigtail Fiber Optic

Network specialists can build a series of connections to end-point devices by splicing the various wires of a multi-fiber trunk together in order to make fiber pigtails. This is one of the main ideas behind fiber pigtails. These installations could also be connected to patch panels or used to facilitate mounting in situations where the precise alignment of hardware components is crucial. It is possible to employ fiber pigtails in the process of cable jetting, which is when communications professionals use advanced ways to install cables in locations that are difficult to access.

Experts in the field of networking believe that the quality of the connectors found on fiber pigtails is of the utmost significance due to the function that they play in connecting various systems. Professionals in the field of networking strive for standards on characteristics such as insertion loss, termination quality, and bend radius.

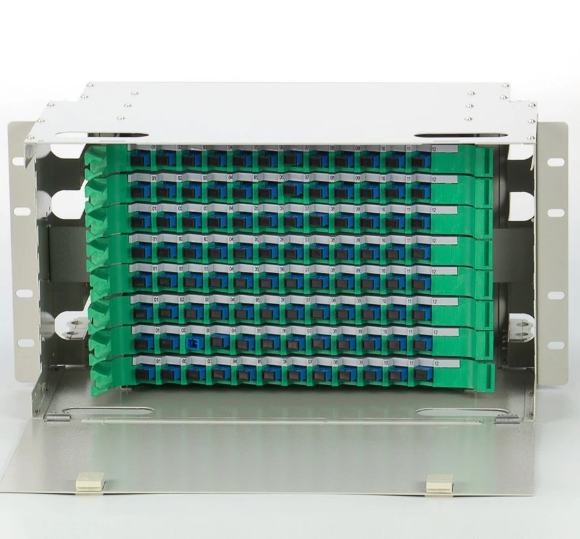

Specification

This is a fiber optic cable that has one end terminated with a connection that was inserted during manufacturing, but the other end is left unterminated. Therefore, one side of the connection can be coupled to various pieces of apparatus, while the other side can be fused with optical fiber cables. Pigtails made of fiber optic material are utilized in the fusion or mechanical splicing processes that are used to terminate fiber optic cables. Fiber optic cable terminations can achieve the highest potential level of performance when high-quality pigtail cables are utilized in conjunction with established best practices for fusion splicing. Pigtails for fiber optic cables can typically be found in ODF, fiber terminal boxes, and distribution boxes among other types of fiber optic management equipment.

Different Types of Pigtails for Fiber Optic Cables

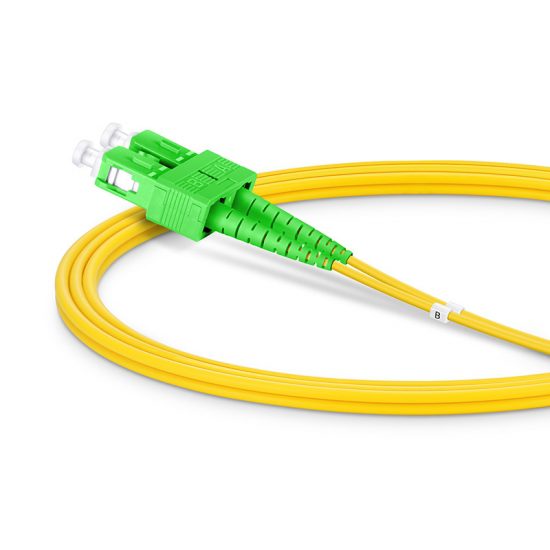

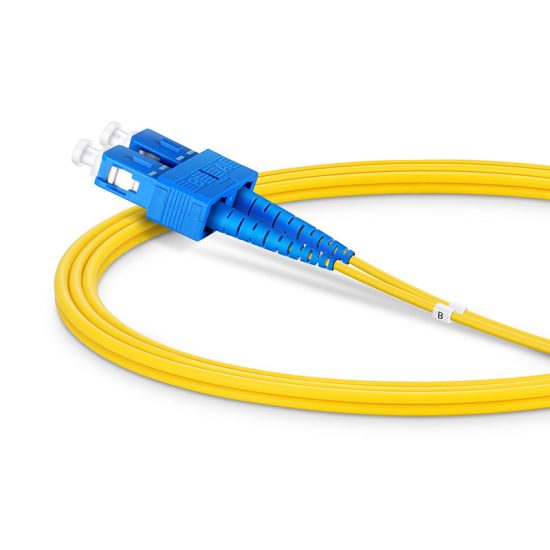

- Pigtail for SC Fiber Optic Cable

The SC pigtail cable connector is a non-optical disconnect connector that has a zirconia or stainless-steel ferrule that is 2.5 millimeters in diameter and has been pre-radiused. The cost of using SC fiber pigtail in applications such as CATV, LAN, and WAN, as well as test and measurement, is relatively low.

- Pigtail for FC Fiber Optic Cable

FC fiber pigtail makes use of the metallic body of FC optical connectors, which has a screw-type structure and high-precision ceramic ferrules. This gives the pigtail several advantages. FC fiber optic pigtails and the goods that are directly related to them are used extensively in a variety of general applications.

- Pigtail connector for ST fiber optic cable

In multimode fiber optic LAN applications, the ST pigtail connector is by far the most common and widely used connector. It is constructed of ceramic (zirconia), stainless alloy, or plastic and features a lengthy ferrule with a diameter of 2.5 millimeters. Because of this, SC fiber pigtails are frequently used in the sectors of sensor technology, manufacturing, medicine, and telecommunications.

In the same way that fiber optic patch cords can be divided into UPC and APC variants, fiber optic pigtails can also be divided in this way. The SC/APC pigtail, the FC/APC pigtail, and the MU/UPC pigtail are the varieties that are utilized the most frequently.

- Pigtail connector for LCB

Designed to help with fiber optic cable testing when utilizing an OTDR. Optical Time Domain Reflectometers (OTDRs) use the OTDR Launch Fiber box to lessen the impact of the launch pulse on measurement errors . It is available in a wide range of fiber lengths and combinations. provided in a sturdy case with a carrying handle and top fastening system. Internal panel obstructed for the fiber’s protection, with labels for the reel’s internal and external connectors. Protected fiber that is at least 2 meters long both on the internal and exterior ends. LSZH 2 or 3 mm external jacket is used. Either SM or MM connections were used to terminate both extremes.